precision casting

precision casting

Is the modern derivation of the ancient lost wax process.

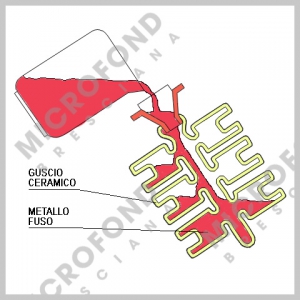

Wax modelsare built, then placed in special tanks that contain synthetic resin and ceramic granules. These two together polymerize, creating a cladding. When the Jet is poured into the form, the wax evaporates, leaving only the piece to solidify.

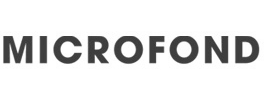

To produce any object you must first make a mold, pointing alternately two techniques:

- preparation of a brass model geometrically identical to detail to produce, but for making a stamping die low melting point alloy

- building from a mold made of aluminum or steel, with one or more representative of particular cavity to produce.

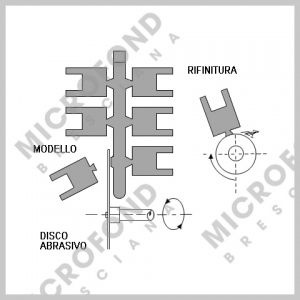

Later, injecting wax into the shell is "print" so many models as there are pieces to be produced (fig. 1).

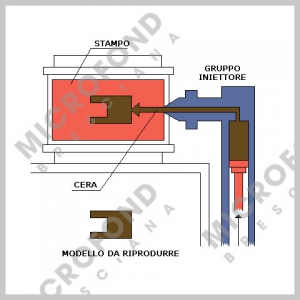

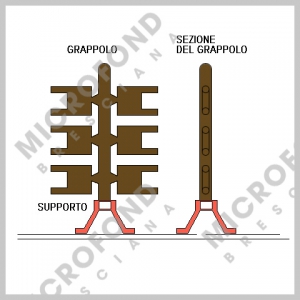

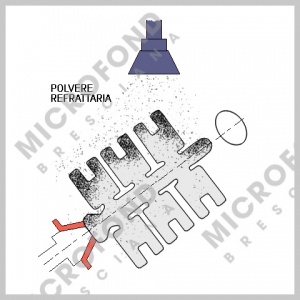

These models are then gathered in a cluster by means of casting attacks (fig. 2), then dipped into a ceramic mixture and finally coated with a refractory material shell powder (fig. 3-4).

This is repeated several times until a shell thick enough to withstand the heat and pressure of molten metal.

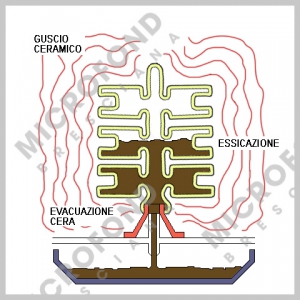

The forms, after the evacuation of the wax (fig. 5), high-temperature furnaces in order to acquire the necessary strength to cast (fig. 6).

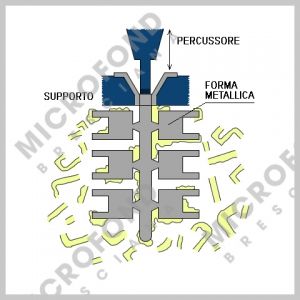

After the cooling of the metal on deletes of ceramic shell using a particular hammer (fig. 7).

Every single piece is finished (fig. 8) and started in the laboratory for quality control.